By mid- August, the grain fields on Grindstone Island had changed to a light brown, the grain heads were full with seeds, the stacks were brown, and it was time for the grain harvest.

Every farmer on the Island owned a grain binder; McCormick-Derring was the most common brand. The grain binder was a rather large, odd-looking machine, with a giant reel or paddle arrangement. The paddle pushed the grain stacks into the cutter bar where the stack was cut and toppled by the paddles on to a canvas belt pushing the stalks to the right on to the two canvas belts. The belts carried the grain upward to the machinery that bound the sheet of grain and tied the bundle with a loop of binder twine and secured the loop with a knot. I will not try to describe the mechanical knotter but somehow – fingers sized the string or twine, rolled a knot, cut the bundle free, and kicked the bundle on to a device. On the binder’s right side – several bundles were retained that were carried along until dumped with a movement by the operator’s right foot. Operating a horse-driven binder was a busy and messy chore. With a team of horses pulling the binder, two hands at least – one hand on the paddle wheel lever to make sure the grain fell onto the canvas belt, keeping the cutter bar at the right height, while seated on a steel seat at the rear of the binder. From this seat, the operator could observe the complete machine in operation; the machine was powered by a ground-driven steel wheel near the center of the rig, while another wheel supported the platform and cutter bar. The entire binding rig had was not a thing of beauty – but it operated beautifully – quite a miracle actually, for when the binder was finished, the bundles were scattered in rows in the fields. The bundles soon would be gathered into groups of 5 or 6 and stood up, heads skyward. These bundles were left to dry in the hot August sun for 2-3 weeks, or until the thresher machine arrived.

My uncle Leon Dano owned the thresher. It was a very large machine and was moved from farm to farm around the island by a tractor, as it was needed. The tractor also provided the power to operate the thresher. There was a large belt from the tractor to the thresher that did the trick. Now the grain bundles that were drying in the fields could be forked by hand on to a wagon and then pitched by hand on to the feeder of the thresher.

The threshing machine was a wonder to look at, as it lay silent – a maze of belts, pulleys, and a multitude of grease fittings, with four steel wheels supporting this great metal monster. The belt that made it operate must have been one foot wide and maybe 40 inches in length. The tractor we used was a Huber, a great machine whose sole purpose was to drive the thresher with the belt and to tow the thresher from one farmland to another. This was an all-day job, as the tractor and thresher moved along very slowly. Concede in position with the tractor running, a belt in line, throttle set, and you were ready to place grain into the machine. A belt hinging to elevator chains, rattling the blower that was sucking air and causing the first bundle of grain to hit the choppers, to dislodge the seed a few feet away. The tractor hardly raised its voice and the thrasher did all of the work. It growled with a cloud of dust, the blast of straw from the blower with the exhaust cap on the tractor sticking straight up hour after hour. The end product was grain that was then gathered into cloth bags and hauled away for storage.

Our farming neighbors and family would come out to help with the work. The lunchtime meal that was prepared, mostly by my mother and grandmother, was better than any high-class restaurant that I’ve ever experienced. The usual main course was fried chicken with a variety of salads, always watermelon, and usually homemade vanilla ice cream and assorted pies. The neighbor ladies all came to catch up on the gossip and there was plenty to talk about on this small island in the middle of the St. Lawrence River.

School started around the first of September and our warm summer fun and lazy days on the River were about to end for the season. The summer for us meant that we fished a lot, rowed our boat around the shores of Grindstone, and would swim in the cool, clear River.

[Photograph notes by Manley Rusho: These photos were taken in 1942 by Elizabeth Bakewell. The photos were taken in fields owned by Elizabeth's husband, Allan Bakewell. The property was once part of the Charles Emery Estate, which included most of the land east of the Delaney Bay Bridge. Mr. Bakewell purchased this land as well as a couple of farms, restored an old grainery, and returned the fields into grain cultivation. Mr. Bakewell died in 1945 and the property was purchased by Barney Hineman. The photos were shared today by Penny Bakewell Linn.]

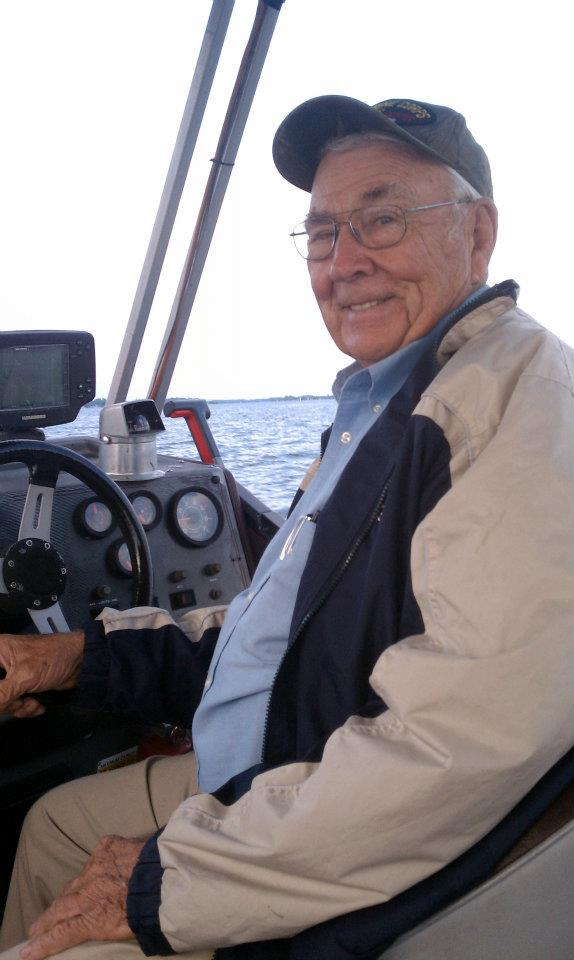

By Manley L. Rusho

Manley Rusho was born on Grindstone Island nine+ decades ago. Last year, in 2021, Manley started sharing his memories with TI Life. (Manley Rusho articles) This Editor and his many friends wish him continued good health and we thank him, most sincerely, for sharing - as the life and times on Grindstone Island are special and should never be forgotten.

Editor's Note: Manley you have done it again! Great article. And we thank you for reminding us that what was good then, is good now: "The summer for us meant that we fished a lot, rowed our boat around the shores of Grindstone, and would swim in the cool, clear River."

Posted in: Volume 17, Issue 9, September 2022, History, Places, People, Photos

Please click here if you are unable to post your comment.